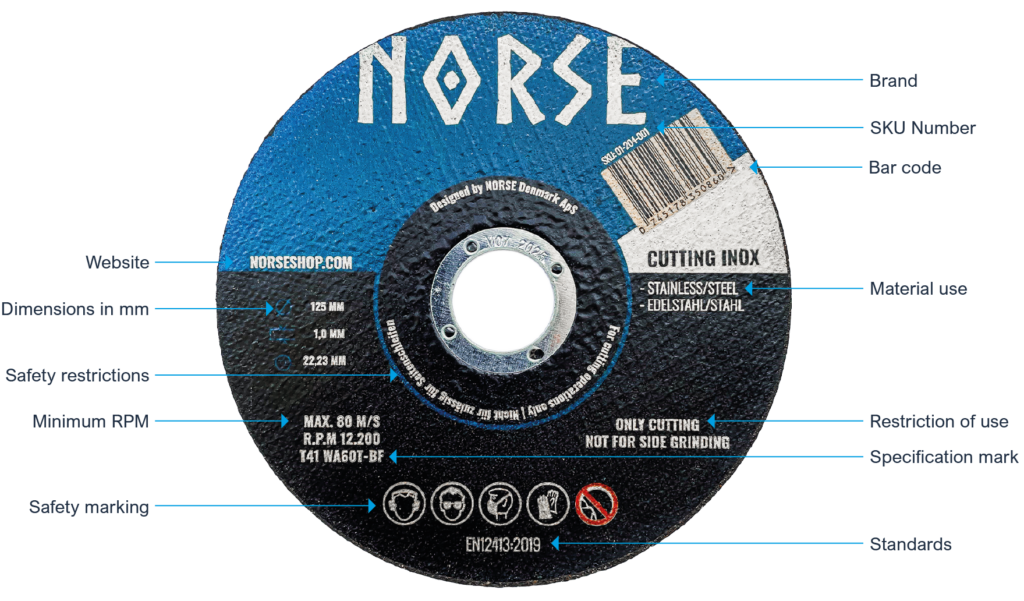

Markings on Abrasive Discs

Common to all cutting and grinding discs at NORSE is that the design contains several different markings. Below you can read more about what the different markings mean.

Standards

First and foremost, discs must comply with the EN12413 (for cutting discs) and EN13743 (for flap discs) standards. In short, EN 12413 specifies requirements and/or measures to eliminate or reduce hazards arising from the design and use of abrasive products. This document also contains procedures and tests to verify compliance with the requirements, as well as safety information for use, which must be made available to the user by the manufacturer. Whereas standard EN 13743 specifies requirements and measures to eliminate and/or reduce hazards arising from the design and use of abrasive tools and their attachment. This standard provides the test method for assessing conformity with both the safety requirements and the safety instruction that the manufacturer must make available to the user.

Disc Type

One of the most common types is a type 1 cutting disc, also known as a type 41 cutting disc, which is completely flat. It is typically considered to be the most efficient type of disc for most cutting applications.

Conversely, instead of being completely flat, a type 27 cutting disc, also known as a type 42 cutting disc, has a depressed center.

The size

The size of the disc is marked as dimensions in millimetres. For example, 125 x 1.0 x 22.23 refers to the diameter, thickness and center hole of the disc respectively.

Specification

The specification of the grinding disc is marked as a series of letters and numbers. For example, T41 WA 60 T BF. This represents the type of disc, the type of abrasive material, the grain size, quality, texture and bond type. A general guide to specification labelling can be found in the table here:

| Example | Marking | Code |

| T41 | Type of disc | Type 41 (Type 1) – flat disc Type 42 (Type 27) – flat disc with depressed centre |

| WA | Type of abrasive | A – regular aluminium oxide WA – white aluminium oxide 19A – mixture of A and WA SD – synthetic diamond ASD – synthetic diamond, metal coating FA – aluminium oxide that is semi-combustible PA – pink aluminium oxide SA (HA) – single crystal aluminium oxide 23A – mixture of A and SA AZ – zirconium oxide C – black silicon carbide GC – green silicon carbide RC – mixture of C and GC |

| 60 | Grain size | Coarse: 10, 12, 14, 16, 20, 24 Medium: 30, 36, 46, 54, 60, Fine: 80, 100, 120, 150, 180 Very fine: 220, 240, 280, 320, 320, 400, 500, 600 |

| T | Quality | Soft: A. B, C, D, E, F Medium: G, H, I, J, K, L, M, N, O, P, Q, R, S, T, U, V Hard: W, X, Y, Z, |

| Structure | (Dense) 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 (Open) | |

| BF | Type of bond | V – Vitrified (Good strength and high porosity) S – Silicate (Waterproof, used for large diameter wheels, fine edge sanding) R – Rubber (Thin discs, fine finish and polishing) RF – Rubber Reinforced B – Resinoid (synthetic resin) (Coarse grinding, high-speed grinding) BF – Resinoid reinforced E – Shellac (Thin discs, high elasticity, not suitable for demanding applications) M – Metal (Typically used for diamond discs) |

Rotational speed (RPM)

The maximum rotational speed is marked on all large sanding discs over 80 mm in diameter in two ways:

- The peripheral surface speed, indicated in meters per second. For example, 80 m/s.

- The rotational speed, expressed in revolutions per minute. For example, 8500 rpm.

For smaller abrasive discs under 80 mm in diameter, the maximum rotational speed is typically indicated on a separate label, which should be kept with the disc At high speeds, colour-coded stripes are also marked across the centre of the wheel. The colours are:

- 50m/s – Blue

- 60m/s – Yellow

- 80m/s – Red

- 100m/s – Green

- 125m/s – Blue/Yellow

The limitations for use are marked on the abrasive disc using a code and, in some cases, a corresponding graphic. The markings used to show restrictions are as follows:

Code Meaning

RE1 Not permitted for handheld and manually controlled grinding

RE2 Not permitted for hand-held cut-off machines

RE3 Not suitable for wet grinding

RE4 Only permitted in fully enclosed work areas

RE6 Not permitted for surface grinding